Improve your production floor operations with EQM Conveyor Systems.

EQM Conveyor Systems help our clients improve many aspects of their business. By installing a Conveyor System specifically designed to address your needs, you get a result that provides tangible benefits on the production floor and, crucially, improves your bottom line.

Here are a few examples of how EQM have made a big difference for our clients in various ways. Click through to each Case Study to read more or contact us

View our conveyor scope form here

Containment of Waste Brings Boost in Efficiency

A New Zealand Bread Company engaged us to help them contain waste in the form of breadcrumbs, which would otherwise mess up the production floor, as well as fouling the internal operations of the Conveyor.

The solution was found in an N-Track Conveyor System, that captured the breadcrumbs due to it’s innovate side-wall conveyor belt design.

READ – “A Clean Sweep for Breadmaker”

Conveyor System Saves More Money Than it Cost in One Season

Moving cartons by a new, specially-designed Conveyor System meant that a Forklift, and a host of health and safety issues associated with its use, simply disappeared for a Hawke’s Bay packhouse.

Much more efficient and safe, the cost of the system was recovered straight away through an investment in efficiency – rather than just doing things as they had always been done.

READ – Packhouse Investment Gets Quick Payback

Custom Conveyor Boosts Punnet Packing Productivity

A two-tier Conveyor System developed to solve production line bottlenecks was developed for a New Zealand Blueberry producer, which has future-proofed the business’s operations as they plan to increase production in coming seasons.

The ingenious solution means that more punnets are packed faster, using a system that now takes up less space on the production room floor.

READ – Blueberry Packing Facillity Increases Productivity

Conveyor Increases Production & Improves Flexibility

An EQM a Multi-lane Slat Band Chain Conveyor helped a honey producer to boost productivity and ease congestion in their Conveyor System, enabling more smooth transfer of Jars across the system.

The design also enables the Manukora Honey team to pack different sized and shaped jars of honey on the same line, massively improving the flexibility of their Conveyor System.

READ – Scaling Up Production by Eliminating Congestion

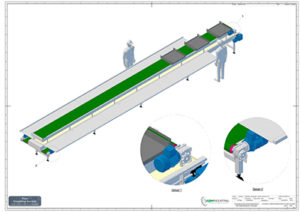

2D & 3D Conveyor Designs Give Ultimate Clarity on Final System

Concept models produced to scale give EQM customers a perfect visualisation of how their EQM Conveyor System will be fitted within their production space and the positioning of associated equipment and staff.

Clients are then able to see through the 2D & 3D design phases exactly what they are getting, with any subsequent modifications boosting the immediate value once the full Conveyor System is eventually built and installed.