Modu Conveyors

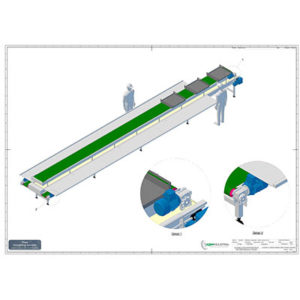

MODU modular conveyors offer cost-effective, flexible solutions for material handling. Their versatility stems from re-assembled components, allowing quick installation or reconfiguration. This modular design facilitates easy realignment, extension, or shortening using basic tools.

Businesses benefit from MODU’s adaptability, optimizing material handling efficiently. Leveraging the modular design and selecting the appropriate series for specific needs leads to cost savings, streamlined operations, and increased productivity.